At last, The Stockings

My Eleonora of Toledo-inspired stockings have been an adventure – with more than its share of misadventure – but they’re done and I’m delighted! [1]

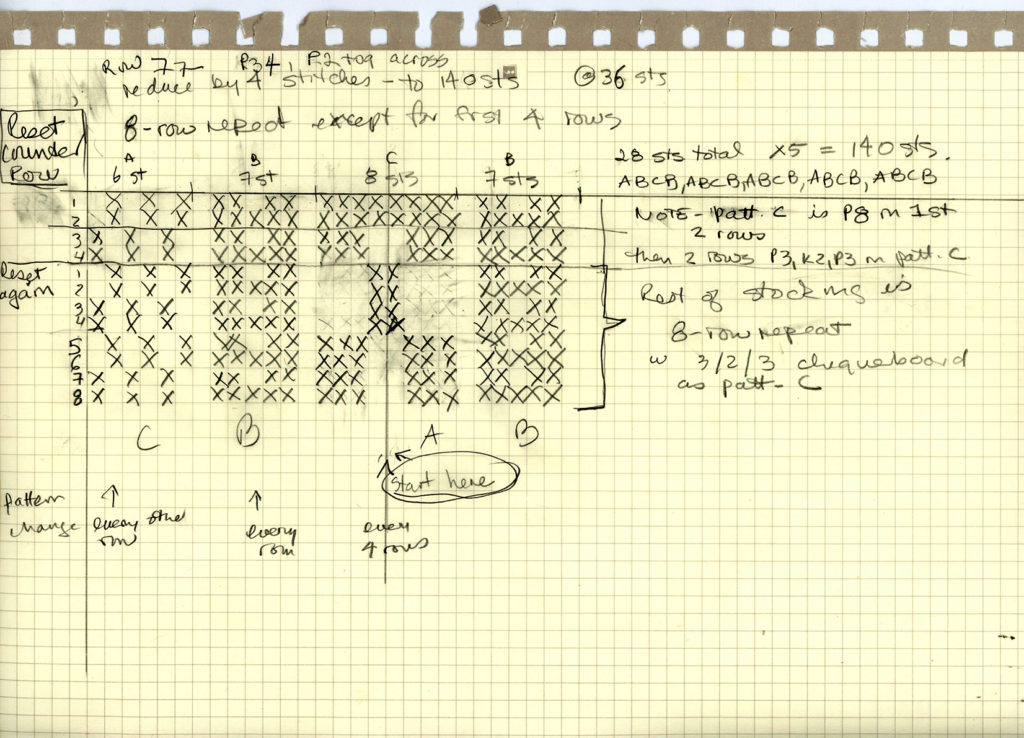

After a couple trial runs, I started work on them five years ago. Though there’s an excellent pattern available on Ravelry [2], it’s in a heavier gauge than I wanted. It’s also faithful to the surface design of the originals, and I wanted to tweak a couple of details.

So I developed my own pattern. Most of it is based it on information gleaned from the Medici Archive, who hold the actual stockings. At the time, they had high-resolution images available on their website. [3]

As I intend to wear the stockings, they are not a line-for-line copy.

- the originals are silk; mine are wool, which I prefer because of its resilience, knitting qualities, comfort – and ease of repair

- the original stockings look baggy in the calf and foot. The decreases for the calf are far too low on the leg to fit me, and the feet are too thick. Perhaps, after at least eleven pregnancies, Eleonora’s feet and ankles were somewhat the worse for wear. Whatever the issues, the stockings wouldn’t have been practical in their original form, so I adjusted the shaping.

In a period-consistent manner, I tweaked minor details of the surface patterning that didn’t appeal to me

- on the cuff, I used purl squares instead of eyelets in the centre of the diamond pattern and omitted the second zigag at the edge

- on the widest leg panel, I substituted a chequerboard pattern for the ladder effect of the originals

- And finally, though the original stockings may have been knit flat and seamed up the back [4], I knit them in the round. Strictly personal preference. By the sixteenth century, knitting in the round was known – the Virgin Mary, in this 15th century painting by Master Bertram of Minden, is clearly knitting a garment in the round

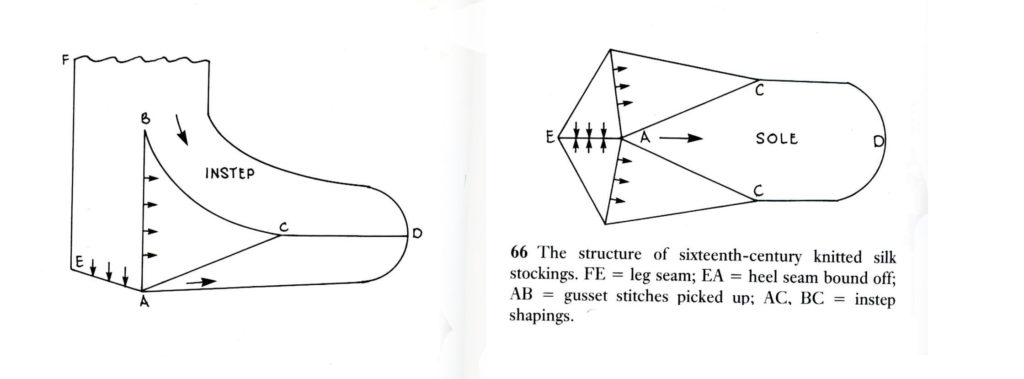

- The heels and feet are mostly educated guesswork. Unfortunately, all the available detailed images were of the stockings in profile. None showed the back of the stocking or the sole face-on, so I based the shaping on Richard Rutt’s diagram of feet of 16th century knitted silk stockings.[5]

That heel pattern has an odd little quirk – since the heel flap is rectangular, there’s a small nub left sticking out when it’s worn. My daughter, who modelled the stockings for the pics, tells me she didn’t even feel it. It’s kinda cute, though I expect it’ll eventually flatten & felt into the sole with wear & sweat.

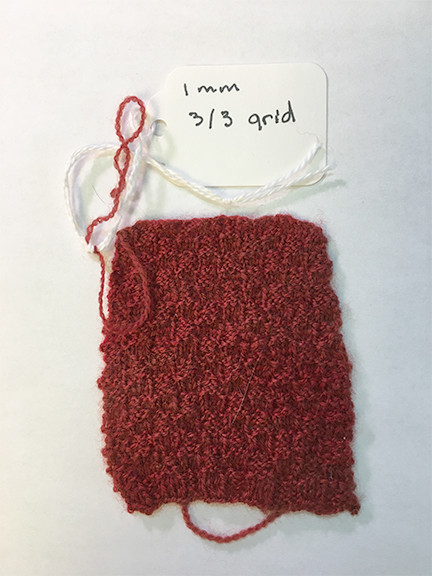

From the Medici Archive images of the stockings, I guesstimated that the originals were knit at ~18-20 stitches per 2.5cm, and found a cobweb-weight yarn in wool white that knits up at 18st/2.5cm on 1mm needles over one of the leg patterns.

I scoured the yarn, dyed it with madder, then overdyed it with cochineal, made a gauge swatch and started knitting.

The first stocking went smoothly. It took about six months, which I felt pretty good about, seeing as I was knitting a complicated pattern on tiny needles in my “spare” time.

With the second stocking, the “adventure” set in.

First of all, when I got the yarn out, I discovered that, for some reason that still eludes me, about half the remaining yarn was darker than the yarn I’d knit the first stocking with. No idea how or why – it was the same dye lot of the same yarn, scoured and dyed at the same time, and had looked the same when I started knitting.

Rather than have an abrupt colour change somewhere, I decided to knit alternating the two shades throughout the stocking, even though it would make the second stocking a bit darker than the first one.

Then I went in for foot surgery, and continued knitting while convalescing.

Big mistake.

Never, ever, work on anything more complex than a garter stitch dishcloth when under the influence of heavy-duty painkillers! I’d nearly finished the second stocking when I realized I’d knit the foot off the wrong side – since the stocking is shaped at the calf, it matters which side the foot comes off of! I ripped it back, reestablished the pattern, and decided to put it away until I was less annoyed with myself.

Life happened, and it was a couple of years before I picked the project up again. At which point I discovered that, though I thought I’d packed it away carefully, moths had gotten at it. I wrapped it up & stuck it in the freezer, where it sat for a year or so.

Finally, I picked it up a couple of months ago, and started darning the moth holes. That took a while – darning many, many, moth holes can be tiresome. Luckily, the surface pattern is so busy that the darns barely show!

When the darning was done, I started knitting the foot again, and discovered that my notes from the first stocking were vague in spots, so I had to reinvent the toe decreases.

My daughter modelled the stockings so that I could take the pics. In the process, a couple more moth-weakened strands gave way, so there was some more darning.

And now the stockings are done. Despite all the mistakes, mends and imperfections, I’m thoroughly pleased with them and eagerly waiting for a suitable SCA[6] event to wear them to!

And just for the fun of it, here’s a pic of the sole. Turned out that the stitch count worked out so that I was able to continue the pattern all the way around the foot!

[1] Because of copyright concerns, I haven’t included an image of the original Eleonora of Toledo stockings. If you want to see an image, and more information, have a look at this article; they’re on page four: https://kemeresearch.com/files/ATR_60_2018_pp3-9_Malcolm-Davies_FINAL.pdf

[2] https://www.ravelry.com/patterns/library/eleonora-di-toledo-stockings-first-edition

[3] The images I used are no longer available on the Medici Archive project at https://www.medici.org/ . I have no idea why.

[4] Currently, there doesn’t seem to be information available on some details of the stockings, including what the gauge is, how the feet were made, and whether they were knit flat or in the round. So, while it’s not 100% certain that they were knit flat, the interpretive text at the Palazzo Pitti, where they’re displayed, said “The closure seam is at the centre back”, and Richard Rutt’s text indicates that 16th century stockings were sewn up the back, so I went with that. Or rather, decided not to go with that.

[5] Richard Rutt, A History of Hand Knitting, Loveland, Colorado, Interweave Press, 1987, p.74

[6] Society for Creative Anachronism